OEM casting mold makers zinc alloy die casting parts for airplanes aircraft

Product Description

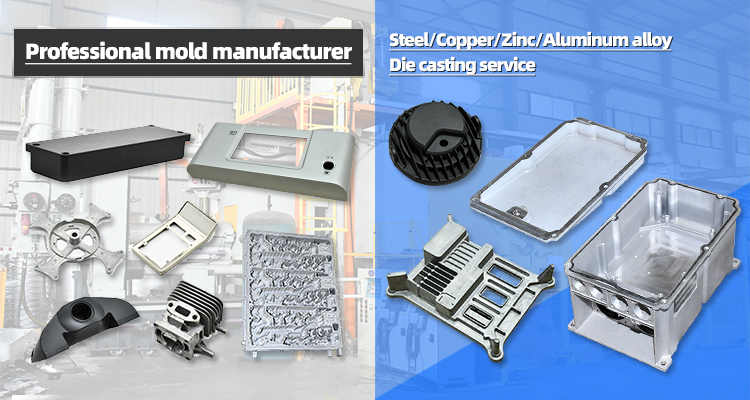

Professional die casting mold factory | ||

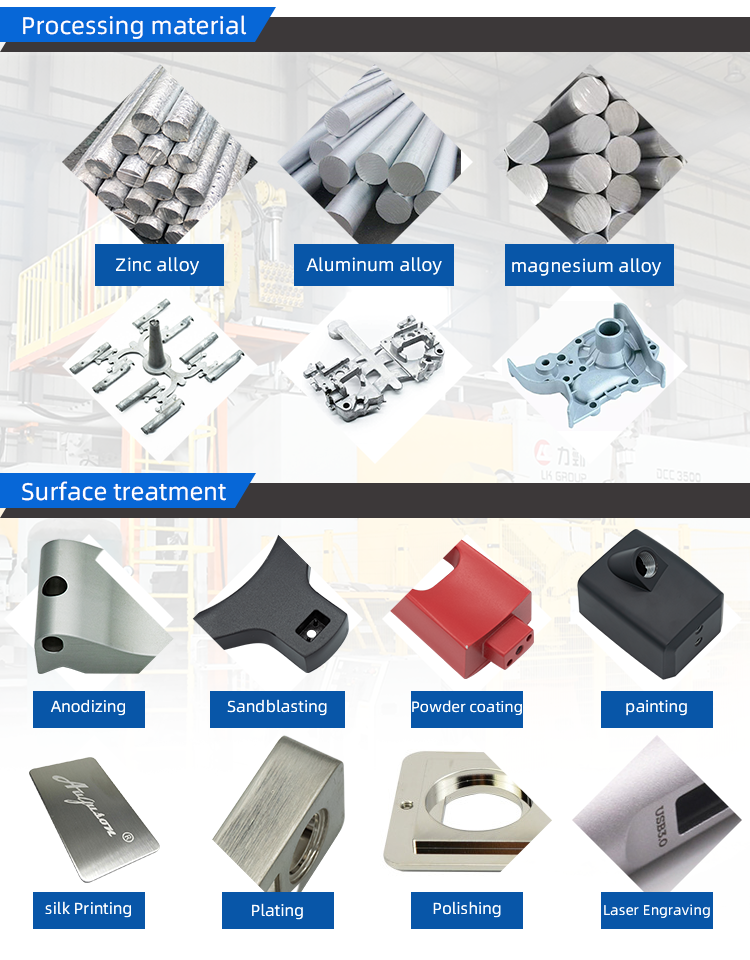

Mould material | H13,2344,8407,8418,SKD61,DAC,FDAC | |

Inspection | 1.Foundry in house: 100% inspection on critical dimension, 100% on appearance 2.Third party inspection available upon requirement | |

Surface treatment | Electroplating,Electrophoresis, Anodization, Painting,Passivation | |

Mainly testing equipment | Zeiss Three dimensional testing instrument(CMM) | |

Mould life | 50000-100,000SHOTS | |

die casting machine | hot/cold/Semi-solid chamber Die casting machine | |

Cavity | Single/Multi Cavity | |

Lead time | 15-25days | |

Package | Standard wooden box /Carton /Or according to customer's requirement | |

Payment terms | T/T,Paypal and so on | |

Terms Of delivery | FOB(Shenzhen port/ Yantian port/Shekou port)/EXW/CFR and so on | |

Certification | ISO9001:2015 | |

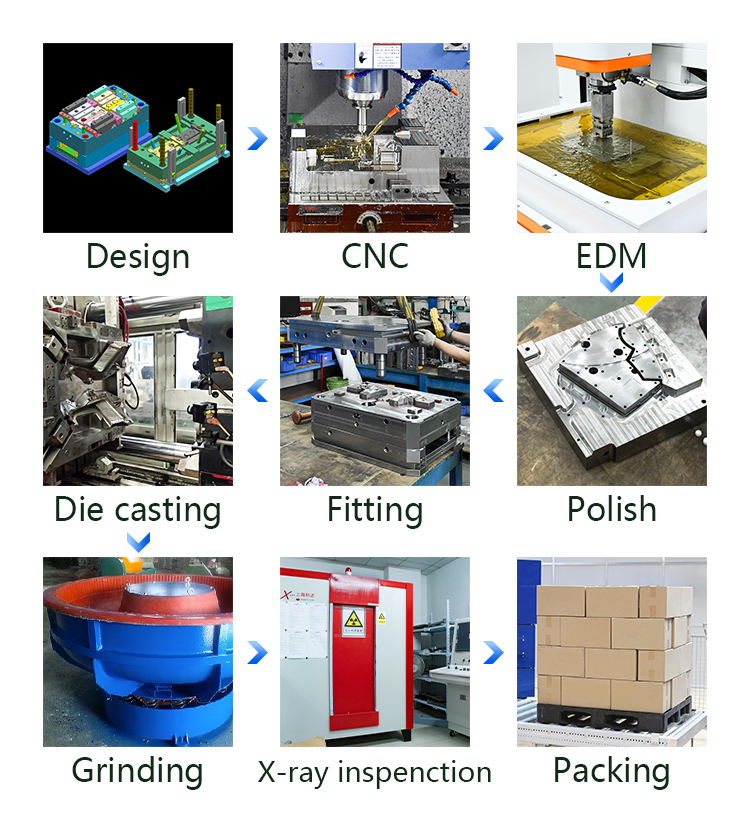

Our Facilities

We have automated casting lines,CNC machining, CMM inspection, Die Casting machine, X-ray, and so on.

Work shop

We have more than 200 skilled workers to ensure the product's quality,and 5s management Professional team and efficient production to provide satisfactory service.

Warehouse

The warehousing and maintenance of molds are free of charge. We will check the mold regularly once every three months to check the status of molds and apply anti-rust oil.

Sample room

Auto Parts, Bathroom Fittings,Lamp radiator,Electronic accessories and Sports equipment, mechanical hardware accessories

Zhonghesheng mold specializes in high quality Plastic Injection Molding and die casting mold with more than 100 employees. It is founded in 2002. At the beginning, we produced the plastic injection molds and the household plastic parts for domestic companies, or some international trade companies. Now we are concentrated in international market. After more than 16 years' development in this industry, we know the international plastic injection molding standards well, such as: HASCO, DME, MISUMI, LKM. Until now, we have produced more than 5000 sets of molds and have been molding millions of Medical plastic parts for Sony, Toshiba, Volvo, Gree, Midea! Our products reach to the range of electronic products, automotive products, home appliances, medical parts and so on.

Zhonghesheng mold specializes in high quality Plastic Injection Molding and die casting mold with more than 100 employees. It is founded in 2002. At the beginning, we produced the plastic injection molds and the household plastic parts for domestic companies, or some international trade companies. Now we are concentrated in international market. After more than 16 years' development in this industry, we know the international plastic injection molding standards well, such as: HASCO, DME, MISUMI, LKM. Until now, we have produced more than 5000 sets of molds and have been molding millions of Medical plastic parts for Sony, Toshiba, Volvo, Gree, Midea! Our products reach to the range of electronic products, automotive products, home appliances, medical parts and so on.

Packing Details :Wooden box for die casting mold , and carbon box for die casting products.

Packing Details :Wooden box for die casting mold , and carbon box for die casting products.Delivery Details : 15-25 days for mould making , and parts delivery time is depends on quantity of production.

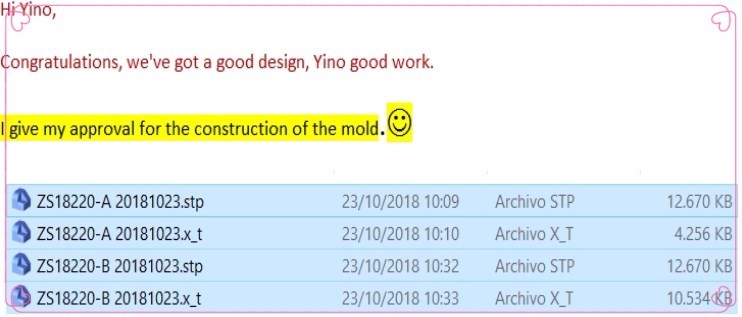

Customer Photos

Customer Photos

FAQ Q1: Are you trading company or manufacturer ?

FAQ Q1: Are you trading company or manufacturer ?A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 15-25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products .

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us if you need more details on Die Cast Airplanes Aircraft. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Zinc Parts Die Casting、Die Casting Zinc Alloy Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Die Cast Airplanes Aircraft. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Zinc Parts Die Casting、Die Casting Zinc Alloy Parts. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Die casting Mould > Zinc Product

Other Products

Hot Products

Barbell Quick Realease Stainless Steel Spring Collar with Rubber GripMultipurpose Deep Ploughing ExcavatorOEM Sand Casting Die Casting Steel Casting Iron CastingWholesale Carbon Steel Perforated Galvanized Square Sign PostLQ cast,foundry,aluminum die castinglow pressure die casting aluminum gas grillaluminum die casting partsOEM gravity casting mould AS Drawingmachining partfan castings for pump,best price fan castingaluminium casting productsresin castingcopper casting product lamp coverQingdao die cast mold , cast alloy aluminumsand casting aluminumcopper impeller