High Precision Custom Made Electroplating High Quality Aluminium Die Casting

Product Description

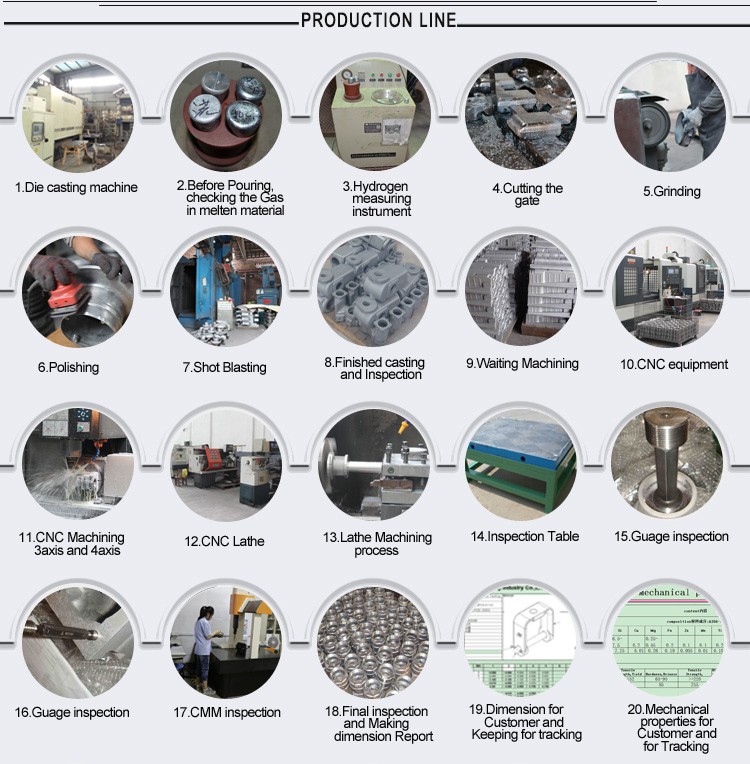

No matter what type of molding you need done, we’re the right supplier for the job.We can do Four types of castings – Aluminum Sand Casting, Gravity die casting, Aluminum Die Casting and Low pressure die casting. Our products include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts.

Welcome to visit our website www.dongruncasting.com

| Material | 1.Sand Casting&Gravity Casting&Low pressure die casting : A356/A319/A413/ZL101/ZL102/ZL104/ZL107/LM6//LM/20/LM25/EN AC-42100/EN AC-42200/EN AC-43000/ EN AC-43200/EN AC-43300/EN AC-43400/EN AC-44200/EN AC-44300/EN AC-46000/EN AC-46200 2.High pressure Die casting : A380/A390/A360/ADC10/ADC12/ENAC-43400/ENAC-44300/ENAC-44400/ENAC-46000/ENAC-46100/ENAC-46200/ ENAC-46500/ENAC-47100 3.CNC machining casting: 6061-T6/6063-T6 |

| Process | Sand casting, Gravity casting, high pressure Die Casting , low pressure die casting and CNC Machining casting. |

| Designs | 1.As per the customer’s drawings 2.As per the customer’s samples |

| Equipment of Casting | 1.High pressure die casting machining: 125T/180T/250T/280T/500T/800T/1250T 2.Gravity casting machine: 5 production lines 3.Low pressure die casting machining: 1 production line 4.Sand casting machine: 6 production lines 5.Degassing equipment and opportunities to refine the material 6.Machining: 5Sets CNC Machines;3 sets Milling machines; 3 sets Turning machines; 10 sets drill and tap machines |

| Testing facility | spectrometer, tensile test machine, hardness test machine, CMM dimension report |

| Certificate | ISO9001:2008/Rosh/SGS |

| Standard | ASTM, DIN,JIS, EN, ISO, GB standards |

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

| Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Product | All kinds of Aluminum Casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

| Advantage | 1.With more than 20years experiencesin aluminum casting; 2.Have four casting types; 3.Near Sea Port and Air Port:Our nearest Port is Ningbo, it takes one and half hour from Shanghai Hongqiao station to our factory(Yongkang City) by fast train 4.Passed ISO9001:2008/Rosh/SGS 5.From Casting to Finished surface, Owned casting, polishing and plating workshops, We can offer Good quality and strict delivery time. 6.With samples and order: We can offer dimension report, Chemical composition and Mechanical properties 7.Control material with spectral and thermal analysis equipment (density and processing) 8.Spectral analysis of raw material and liquid melt, batch before casting. |

| Inspection | 1.Foundry in-house 2.Third Party inspection available upon requirement |

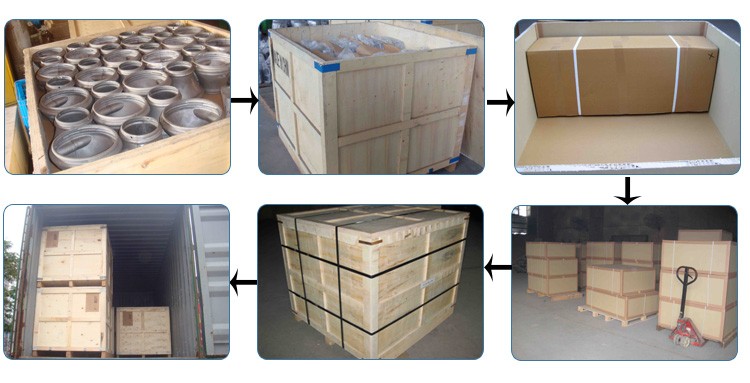

| Packing | Carton Box with Pallet/Wooden Box/Steel Pallet |

During many of the procedures and upon completion of all the machining operations, Dongrun Casting performs quality checks to ensure the manufactured part meets the exact customer specifications.

We use a variety of testing instruments including "go or no-go" gauges (to determine if threads or other dimensions holes are correct), micrometers, height gauges, calipers, thread gauges, bore gauges and ring gauges. We test and certify these gauges regularly.

We also have a specialized unit for pressure testing our castings. It measures pressure loss for castings that will be used in liquid or air applications. This testing and certification is also available to our customers with their shipped product.

Dongrun Casting also has full CMM (Coordinate Measuring Machine) capabilities and can supply this data to our customers with their 1st article reports. This CMM has greatly reduced our time in measuring new and full production parts and allows us to measure dimensions that would be difficult otherwise.

Specific casting control measures include: Heat Treat Certification, Hardness Testing, First Article Inspection.

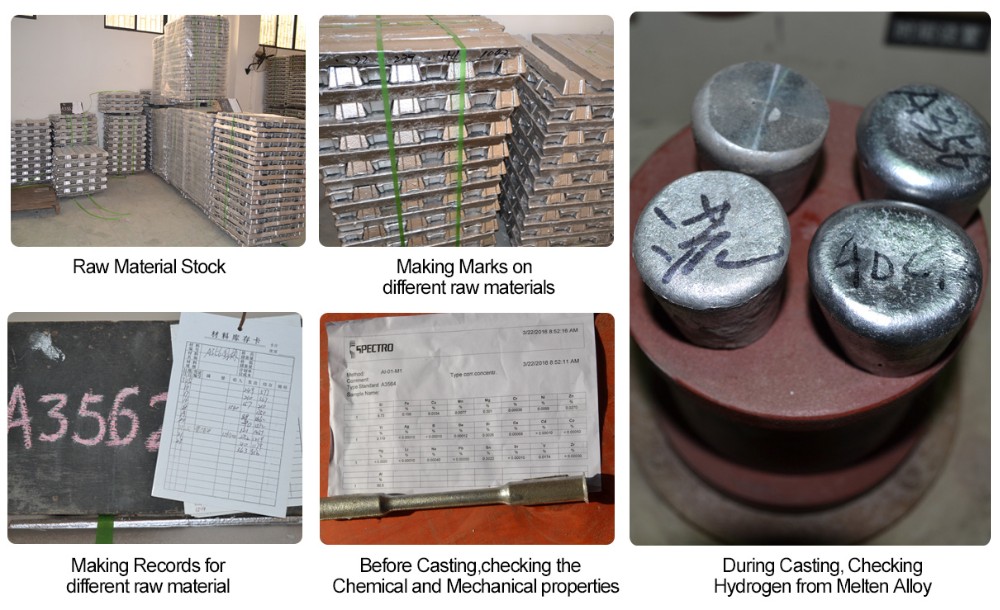

About the raw material, it is very important for casting. Before casting, we will do testing bar to check the Chemical composition and Mechanical properties. In our raw material warehouse, we are doing the marks on each type material. Free from the mistake when the workers melt the raw material.

Market | Total revenue(%) |

North America | 40% |

Eastern Europe | 5% |

Western Europe | 20% |

Northern Europe | 10% |

Middle East | 5% |

Oceania | 5% |

Domestic Market | 15% |

A. Tooling and Samples:

1) Sand casting, within 20-30days after getting order

2) Die casting, within 40-50days after getting order

3) Gravity casting, within 30-40days after getting order

B. Productions:

After getting order 30-40days.If you have very urgent order, we can check it the

best delivery time for you.

1) Exported Standard pallets included carton package

2) Exported Standard Wooden crate

3) Do package as Customer required

1. With more than 20years in Aluminum casting;

2. Have four casting types;

3. Near Ningbo and Shanghai Sea Port,Near Hangzhou and Yiwu Air port.And take G trains from Shanghai Hongqiao Station to Yongkang Nan station(our City) about two and half hours.

4. From Casting to Finished surface, Owned casting,polishing and plating workshops, We can offer Good quali ty and strict delivery time.

5. With samples and order: We can offer dimension report,Chemical composition and Mechanical properties

6. Control material with spectral and thermal analysis equipment (density and processing)

7. Spectral analysis of raw material and liquid melt,batch before casting.

Thank you to browse our online showroom. If you want to know more about our factory, pls visit our website www.dongruncasting.com

And then email us your inquiry today, we will send you price list in 48hours.

Product Categories : TOPSALE PRODUCTS

Premium Related Products