High precision plastic medical device injection mold plastic injection molding parts

Product Description

Product Description

Product Name | High precision plastic medical device injection mold plastic injection molding parts | ||||||

Material | ABS/PC/PP/PVC/PA/PMMA/PBT | ||||||

Mould material | P20/718/738/S136/2738/2316 | ||||||

Design software | UG PROE CATIA SOLIDWORK CAD | ||||||

Mould base | LKM.HASCO.DME | ||||||

Mould life | 300000-500000 shots | ||||||

Keyword | High precision plastic medical device injection mold plastic injection molding parts | ||||||

Color | Customized Colors | ||||||

Cavity | Single Cavity\ Multiple Cavity | ||||||

Runner | Hot Runner\ Cold Runner | ||||||

Main technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, Dimension test, etc. | ||||||

Certificate | ISO9001: 2015 | ||||||

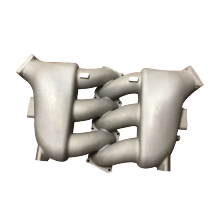

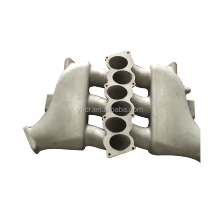

Products Show

Our Service

1. We are professional plastic mold making factory and we can design and produce any multifunctional materials plastic injection parts according to customers' requirements.

2. We know the quality is the soul of the enterprise and we have power to make plastic injection mold and we must make high quality and high precision plastic multifunctional materials plastic injection parts, only like that we can acquire customer's trust.

We have rich experience in plasticmultifunctional materials plastic injection parts design and making.

2. We know the quality is the soul of the enterprise and we have power to make plastic injection mold and we must make high quality and high precision plastic multifunctional materials plastic injection parts, only like that we can acquire customer's trust.

We have rich experience in plasticmultifunctional materials plastic injection parts design and making.

Our Company

Zhonghesheng mold specializes in high quality plastic mold, with more than 100 employees. It is founded in 2002. At the beginning, we produced the multifunctional materials plastic injection parts for domestic companies, or some international trade companies. Now we are concentrated in international market. After more than 16 years' development in this industry, we know the international multifunctional materials plastic injection parts standards well, such as: HASCO, DME, MISUMI, LKM. Until now, we have produced more than 5000 sets of plastic injection mold and have been molding millions of multifunctional materials plastic injection parts! Our plastic injection mold produced products are reach to the range of electronic products, automotive products, home appliances and so on.

Equipped with the most advanced software for designing, analyzing and manufacturing, Zhonghesheng Mold has imported a lot of high precision plastic injection mold machines from Taiwan and Japan, including High Speed CNC, Mirror EDM, Wire Cutting Machine, and CMM Inspection Machines and so on to guarantee high standard plastic injection mold quality.

Zhonghesheng Mold consider "higher quality, lower cost and punctual delivery" as the primary business philosophy. Based on professional,people-oriented, and customer-centered management, Zhonghesheng Mold takes "customer - oriented, Quality first" as company's aim,committed to provide clients with multifunctional materials plastic injection parts and overvalued services by right of advanced technologies, scientific management and constant improvements.

Equipped with the most advanced software for designing, analyzing and manufacturing, Zhonghesheng Mold has imported a lot of high precision plastic injection mold machines from Taiwan and Japan, including High Speed CNC, Mirror EDM, Wire Cutting Machine, and CMM Inspection Machines and so on to guarantee high standard plastic injection mold quality.

Zhonghesheng Mold consider "higher quality, lower cost and punctual delivery" as the primary business philosophy. Based on professional,people-oriented, and customer-centered management, Zhonghesheng Mold takes "customer - oriented, Quality first" as company's aim,committed to provide clients with multifunctional materials plastic injection parts and overvalued services by right of advanced technologies, scientific management and constant improvements.

Factory

Our Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

Packing & Delivery

wooden case for plastic injection mold;

carton case for multifunctional materials plastic injection parts.

carton case for multifunctional materials plastic injection parts.

Our Certifications

Zhonghesheng mold is strongly committed to quality of plastic injection mold and multifunctional materials plastic injection parts and quality control systems are accredited to ISO 9001: 2015, the document control system goes through all the production and quality control inspection process. We own a full set of advanced measuring and testing equipment, the quality control staff who can provide a series of testing reports upon customer's request at any time.

Customer Photos

FAQ

Q1: Are you trading company or manufacturer ?

A: We are totally a factory, having our own's factory building and injection mold making equipment. We warmly welcome you to visit our factory and look forward to meeting you.

Q2: What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU or according to customer's requirement.

Q3: How long is your delivery time?

A:Generally, it will take 15 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order of multifunctional materials plastic injection parts.

Q4:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q5: Do you provide samples ? is it free or extra ?

A:Yes, We can supply the sample if we have ready plastic multifunctional materials plastic injection parts in stock, but the customers have to pay the courier cost.

Q6: Can you produce according to the samples?

A: Yes, we can produce plastic injection mold by your samples or technical drawings. We can build the multifunctional materials plastic injection parts and fixtures.

Q7: What is your terms of payment ?

A: Plastic lighter mold payment : T/T 40% deposit with po, 30% after first trial shot, 30% before shipment;

Lighter cover or plastic lighter cover payment : T/T 40% deposit with po, 60% before shipment;

Lighter cover or plastic lighter cover payment : T/T 40% deposit with po, 60% before shipment;

Q8: What is your terms of packing?

A:Generally, we pack the plastic injection mold and pack the multifunctional materials plastic injection parts in the PP bags or according to your requirements..

Q9:How do you make our business long-term and good relationship?

A:1. We keep good quality of plastic injection mold or multifunctional materials plastic injection parts and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Product Categories : Plastic Injection Moulding > Plastic Injection Moulding

Premium Related Products

Other Products

Hot Products

Barbell Quick Realease Stainless Steel Spring Collar with Rubber GripMultipurpose Deep Ploughing ExcavatorOEM Sand Casting Die Casting Steel Casting Iron CastingWholesale Carbon Steel Perforated Galvanized Square Sign PostLQ cast,foundry,aluminum die castinglow pressure die casting aluminum gas grillaluminum die casting partsOEM gravity casting mould AS Drawingmachining partfan castings for pump,best price fan castingaluminium casting productsresin castingcopper casting product lamp coverQingdao die cast mold , cast alloy aluminumsand casting aluminumcopper impeller