new ideas custom plastic medical products injection mold making

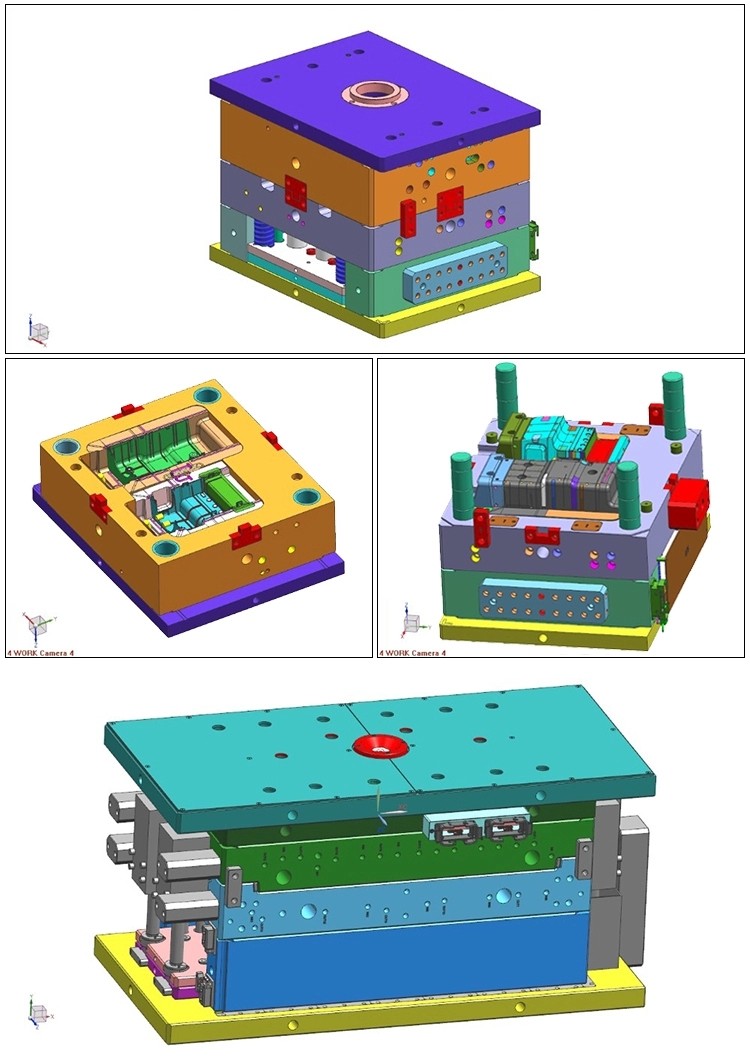

Product Description

Product Name | 2019 new ideas custom plastic medical products injection mold making |

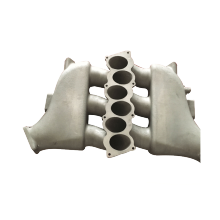

Mold Material | S136, P20, NAK80, 2316,2738,Din2344,H13 and available |

Product Material | ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc. |

Mold Base | LKM or by requested |

Runner System | Hot/Cold Runner |

Cavity | Single cavity, multi cavity by requested |

Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, and 2.5 Dimension test, etc. |

Finish | Texture,Corrosion word, Mirror finish, Brushed |

Mould standard | HASCO, DME, MISUMI, or by requested etc. |

Design Time | 3 days |

Moldlife | 300000-500000 shots |

Certificate | ISO9001:2015 |

1-Zhonghesheng mould provide high quality injection molded plastic parts injection molding service

2-Customized plastic parts injection molding can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect.

3-Different plastic parts injection molding can pass different certififcation such as UL test, V0 fire resistant test,REACH test,SGS test and IP65.

4-Zhonghesheng mould can also provide different surface treatment for plastic parts injection molding. Commonly use surface treatment for plastic parts injection molding as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI.

6-Beside mold making and plastic parts injection molding ,we also provide printing,welding, assembly and packing service.

Custom ABS different colors plastic molding for injection plastic cup parts moulding

Custom ABS different colors plastic molding for injection plastic cup parts moulding

Zhonghesheng mould specializes in high quality custom injection molded plastic parts injection molding service with more than 100 employees. At the beginning, we produced the plastic injection mold and injection molded plastic parts for domestic companies, or some international trade companies. Now we are concentrated in international market. After more than 16 years' development in this industry, we know the international mold standards very well, such as: HASCO, DME, MISUMI, LKM. Until now, we have produced more than 5000 sets of plastic injection molds and have been molding millions of injection molded plastic parts for Sony, Toshiba, Volvo, Gree, Midea! Our products reach to the range of electronic products, automotive products, home appliances and so on in ABS, PC, PP, ABS, PEC, PVC, PA66, PEEK, PPC, PBT, PPS etc materials.

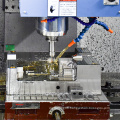

Equipped with the most advanced software and Moldflow for designing, analyzing and manufacturing, Zhonghesheng mould has imported a lot of sets high precision tooling machines from German and Japan, including High Speed CNC, EDM, Wire Cutting Machine, and CMM Inspection Machines and so on to guarantee high standard product quality.

Zhonghesheng mould persists in higher quality, lower cost, punctual delivery as the primary business philosophy. Based on professional, people-oriented, and customer-centered management, Zhonghesheng mould takes "customer - oriented, Quality first" as company`s aim, committed to provide clients with high quality products and overvalued services by right of advanced technologies, scientific management, and continues improvement.

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Sales Team

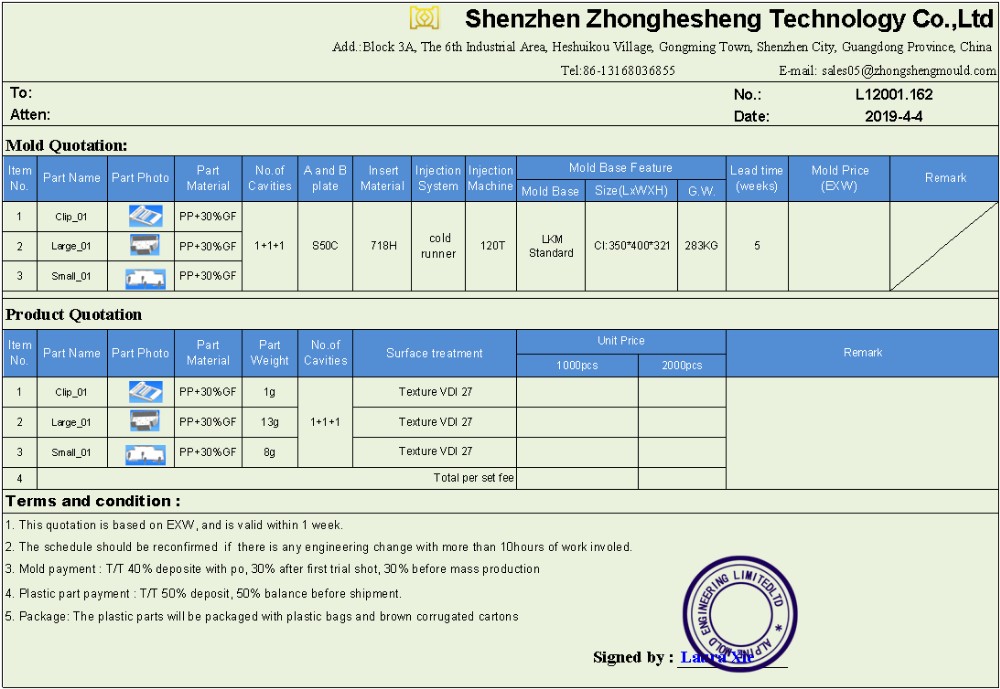

1) QUOTATION SHEET

2) DFM Report and Mold Design

After you confirmed order, we provide engineering guidance to help you design moldable parts that are optimized for manufacture. From mold design concepts to process development and validation, we ensure that all aspects of production meet the ultimate goal of producing.

3) Weekly Report

During the mold making, we will send you the weekly report each week to keep you noted about the mold progress. And make sure our quality and delivery time to avoid any delay.

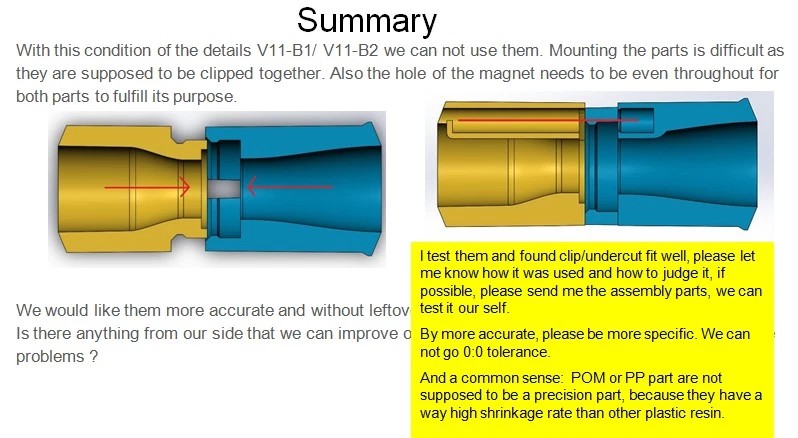

4) Sample Inspection Report

After you test samples, if there is something about the sample which are not ok, we will make a note for mold changes or modifying. In this note, we will point the problem, the relative solution, the time as well as the time needed.

5) Plastic molding for mass production

After the sample is confirmed, then we will do the mass production as required. With our experienced mold makers and setters we can achieve optimum product output in a minimum of time. Your product is molded to your specifications and put through our quality inspection department to guarantee accuracy and quality at all times.

6) Assembly and Package

Fully capable of managing secondary operations, silk printing, painting, assembly and even final packaging ready for shipment to your warehouse.

PACKAGE FOR plastic injection mold: Coat with anti-rust oil and profective film, put into wooden box with files.

DELIVERY by sea, by air or by express

PACKAGE FOR plastic molding: PP bags+carton case+pallet

DELIVERY by sea,by air or by express

Zhonghesheng mould is strongly committed to quality and quality control systems are accredited to ISO 9001: 2015, the document control system goes through all the production and quality control inspection process. We own a full set of advanced measuring and testing equipment, the quality control staff who can provide a series of testing reports upon customer's request at any time.

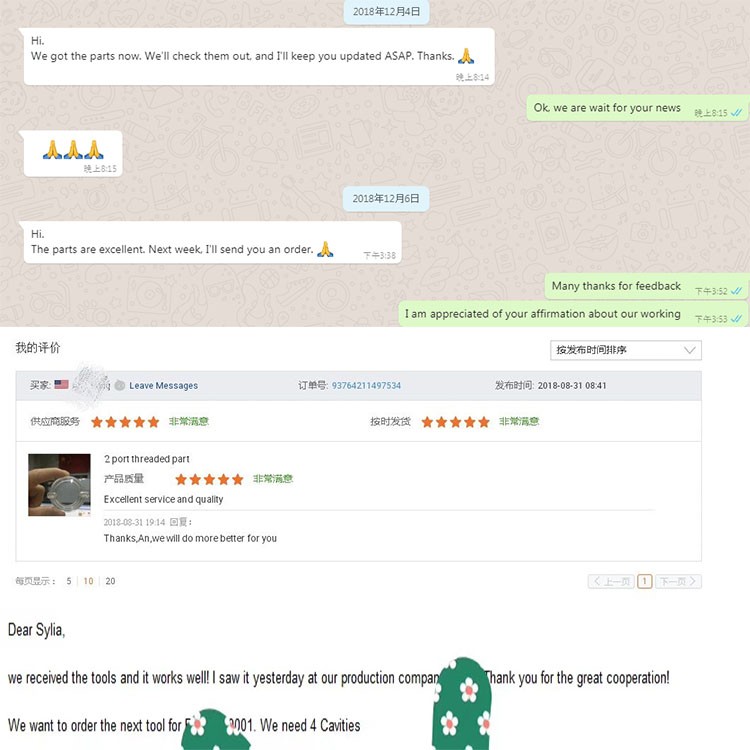

Geoff from Canada

Shenzhen Zhonghesheng mould as our Long terms cooperative partner.

We already ordered a total of 100,000 styles plastic molding. The most important reason why we choose Zhonghesheng mould is the high quality and punctual delivery.

Ali from UK

Plastic molding, we choose Zhonghesheng mould, we are running car accessories company.

All of our customized injection plastic case must be with special tastes design and also should keep high quality.

Zhonghesheng mould have this production power to guarantee that.This why we alway choose them.

Q1.Are you a factory or a trading comapny?

A:We are totally a factory, having our own's factory building and Plastic Injection Mould and plastic parts injection molding equipment. We warmly welcome you to visit our factory and look forward to meeting you.

Q2. What is your terms of packing?

A: Generally, we pack the plastic injection mold in wooden case and pack the plastic parts injection molding with carton case.

Q3. What is your terms of payment?

A: Mold payment : T/T 40% deposit with po, 30% after first trial shot, 30% before shippment;

Part payment : T/T 40% deposit with po, 60% before shippment;

Q4. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU or according to customer's requirement.

Q5. How about your delivery time?

A: Generally, it will take 15 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q6. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q7. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q8. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q9.How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Product Categories : Plastic Injection Moulding > Medical plastic parts

Premium Related Products