Zhonghesheng mould as our Long terms cooperative partner.

We already ordered a total of 100,000 styles plastic products. The most important reason why we choose Zhonghesheng mould is the high quality and punctual delivery.

high quality plastic injection product custom mould servise

Product Description

high quality plastic injection product custom mould servise

Product Name | high quality plastic injection product custom mould servise |

Mold Material | S136, P20, NAK80, 2316,2738,Din2344,H13 and available |

Product Material | ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc. |

Mold Base | LKM or by requested |

Runner System | Hot/Cold Runner |

Cavity | Single cavity, multi cavity by requested |

Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, and 2.5 Dimension test, etc. |

Finish | Texture,Corrosion word, Mirror finish, Brushed |

Mould standard | HASCO, DME, MISUMI, or by requested etc. |

keywords | plastic injection product |

Moldlife | 300000-500000 shots |

Certificate | ISO9001:2015 |

1. Our efforts on mold quality:

A good design is the gurantee for good quality--our engineer department is consisted of 25 rich experienced engineers, they could work both on 2D and 3D mold design, also we could do moldflow analysis for big and complex mold.

Steel quality--the most used steels are P20, 1.2344, 1.2738, NAK80, 718H, 420SS, H13, ASSAB8407, ASSAB 8401..., but steel brand could be nominated by customers, and all the original steel certification will be shipped together with the mold.

Steel Heat treatment are outsourced, and we will do hardness test when steel get back to home.

And , every mold test will be recorded with video! And inspect the samples full dimensions to report to the customer, also injection parameters will be shared.

2. How to go with a business with the offshore mold maker of Desem?

1) Send us quotation with your part drawing--generally it take 2-3 working days, and our price is based on FOB Shenzhen, mold structure information, steel information, mold life, lead time, payment terms all will be specified in the quotation sheet.

2) P.O. confirmed--

2.1--DFM stage--include the mold's spec., standard, parting line layout, draft issue, gate details, cooling, ejection layout, cam structures, surface requirements--this DFM is an PowerPoint file, will send to customer side for confirmation.

2.2--2D&3D mold design--this is started based on the DFM confirmed info., the tooling will be only started with the approval of the customer side.

3) Tooling stage--weekly progress report will be sent on every Monday, with the lastest machined photos attached in the file.

4)Mold test--will take testing video and upload to ftp site for customer checking, and will offer 10-20 shots free samples delivered to customer side for assembly checking and functional checking. Will offer molding parameters to customer, and also the full dimensions inspection reports!

5)Mold shippment--2D,3D mold drawing, final molding parameters, mold testing video, steel certifications, spare parts, electrodes, all these will be shipped together with the molds.

Zhonghesheng mould specializes in high quality plastic injection molding with more than 200 employees. At the beginning, we produced the injection moulds and plastic products for domestic companies, or some international trade companies. Now we are concentrated in international market. After more than 16 years' development in this industry, we know the international mold standards very well, such as: HASCO, DME, MISUMI, LKM. Until now, we have produced more than 5000 sets of molds and have been molding millions of plastic products for Sony, Toshiba, Volvo, Gree, Midea! Our products reach to the range of electronic products, automotive products, home appliances and so on in ABS, PC, PP, ABS, PEC, PVC, PA66, PEEK, PPC, PBT, PPS etc materials.

Equipped with the most advanced software and Moldflow for designing, analyzing and manufacturing, Zhonghesheng mould has imported a lot of sets high precision tooling machines from German and Japan, including High Speed CNC, EDM, Wire Cutting Machine, and CMM Inspection Machines and so on to guarantee high standard product quality.

Zhonghesheng mould persists in higher quality, lower cost, punctual delivery as the primary business philosophy. Based on professional, people-oriented, and customer-centered management, Zhonghesheng mould takes "customer - oriented, Quality first" as company`s aim, committed to provide clients with high quality products and overvalued services by right of advanced technologies, scientific management, and continues improvement.

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

Packing Details : Wooden case for plastic injection moulds,carton case for plastic products

Delivery Details : FOB shenzhen or shekou or by air by express

Zhonghesheng mould is strongly committed to quality and quality control systems are accredited to ISO 9001: 2015, The document control system goes through all the production and quality control inspection process. We own a full set of advanced measuring and testing equipment, the quality control staff who can provide a series of testing reports upon customer's request at any time.

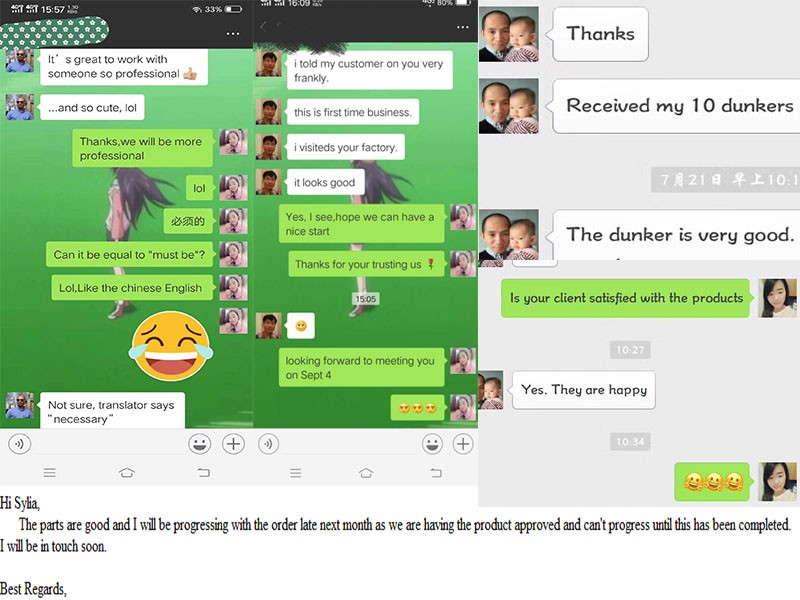

Geoff from Canada

Ali from UK

Plastic products manufacturer, we choose Zhonghesheng mould, we are running car accessories company.

All of our customized parts product must be with special tastes design and also should keep high quality.

Zhonghesheng mould have this production power to guarantee that.This why we alway choose them.

Q1.Are you a factory or a trading comapny?

A:We are totally a factory,having our own's factory building and plastic injection molding equipment.We warmly welcome you to visit our factory and look forward to meeting you.

Q2. What is your terms of packing?

A: Generally, we pack the plastic injection mold in wooden case and pack the plastic products in the PP bags or according to your requirements.

Q3. What is your terms of payment?

A: Mold payment : T/T 40% deposit with po, 30% after first trial shot, 30% before shippment;

Part payment : T/T 40% deposit with po, 60% before shippment;

Q4. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU or according to customer's requirement.

Q5. How about your delivery time?

A: Generally, it will take 15 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q6. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q7. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q8. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9.How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Product Categories : Plastic Injection Moulding > Electronic plastic housing

Premium Related Products