Our customer from UK are visiting our factory, and have a deep impressive in our factory, our sales manager show our factory around to him and discuss the details of project with him.

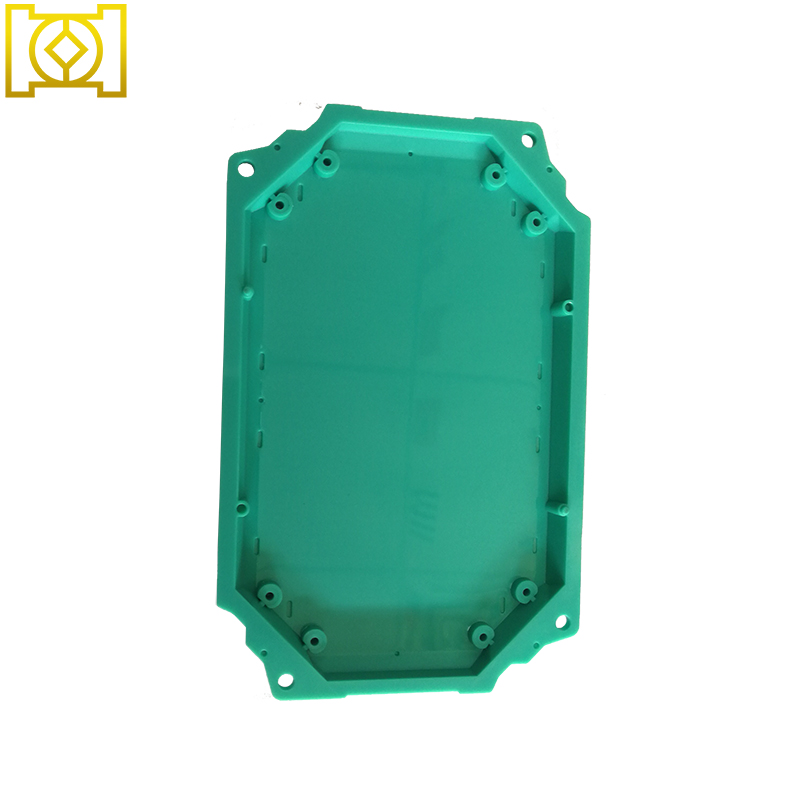

Custom ABS PC PEEK PP PA GF plastic cover injection mouldings parts with mold making for electronic device

Product Description

1. Grade: food grade , medical grade

2. Size: customized

3. Standard: OEM

4. Certification: ISO9001:2015

Product Name | Custom ABS PC PEEK PP PA GF plastic cover injection mouldings parts with mold making for electronic device |

Material | PC, PP , ABS, POM, PC, PP, PA66, ,,,,, |

Color | customized |

Standard | Hasco,DME,,,,, |

Mold life | 100000--800000 shots |

Certification | ISO9001: 2015 |

Place origin | Shenzhen China |

Pay term | FOB Shenzhen |

Similar products :

Army culture

For army culture, it means if we promise it, we will finish it on time without any excuse.

Family culture

For family culture, all the workers of Alpine Mold is a big family. It means that "Your business is also my business", when you have any need, we will do our best to help you

School culture

school culture. There is an saying in China say that "you will never be too old to study". So Alpine Mold will usually gather the workers together to study inside and outside our company. The study includes the working skills, management skills and some of our Chinese traditional culture.

customize Plastic molded products OEM injection ABS Plastic Products, Plastic injection molding mould, Plastic Injection Moulding factory show:

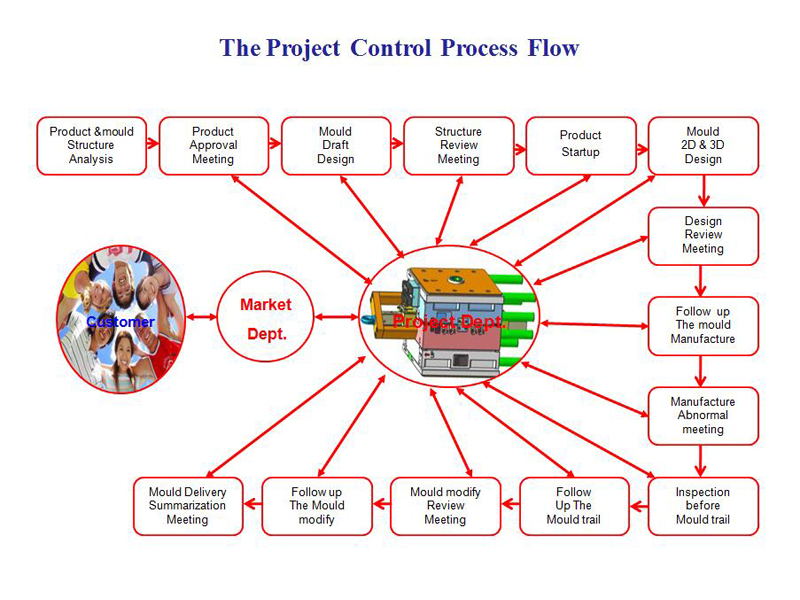

Equipped with the most advanced software for designing, analyzing and manufacturing, Zhongsheng Mould has imported a lot of sets high precision tooling machines from German and Japan, including High Speed CNC, EDM, Wire Cutting Machine, and CMM Inspection Machines and so on to guarantee high standard product quality.

Zhongsheng Mould as a professional abs plastic cover injection mouldings parts with mold for electronic device manufacturer, we persists in higher quality, lower cost, punctual delivery as the primary business philosophy. Based on professional, people-oriented, and customer-centered management, Zhongsheng Mould takes "customer - oriented, Quality first" as company`s aim, committed to provide clients with high quality products and overvalued services by right of advanced technologies, scientific management, and continues improvement.

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

Packing Details :Wooden box for plastic injection molding mould. and carbon box for abs plastic cover injection mouldings parts

Delivery Details : 25-35 days for molding mould , and parts delivery time is depends on quantity of production.

1. Special logistics packaging

2. Suitable carton size

3. Shock bubble film

customize plastic case injection mouldings parts, plastic injection mold, plastic injection molding quality control

ISO 9001 : 2015

ISO 9001: 2015 certified, As a professional abs plastic cover injection mouldings parts with mold for electronic manufacturer , Zhongsheng mould is strongly committed to quality control system. The document control system goes through all the production and quality control inspection process. We own a full set of advanced measuring and testing equipment, the quality control staff who can provide a series of testing reports upon customer's request at any time.

Main QC documents:

1. Supplier audit procedures

2. Product identification and products plasticity process

3. Incoming material inspection procedures

4. Inspection procedures for the production process

5. Final and ex-work inspection procedures

6. Inspection and test status of the control procedures

7. Nonconforming product control procedure

8. Corrective and preventive measures control procedures

9. Customer complain control procedure

We have set up an integrated quality management system and we will keep improving ourselves to make sure all the parts is in perfect quality finally.

Favorable Comment

Favorable Comment

after meeting , we have dinner together, they said the Chinese food is great.

Favorable Comment

Our customer from UK are visiting our factory, and have a deep impressive in our factory, our sales manager show our factory around to him and discuss the details of project with him.

FAQ of customize plastic injection mouldings parts, plastic injection molding, Plastic Injection Mould factory

Q: Are you trading company or manufacturer ?

A: We are 100% direct factory.

Q: How long is your delivery time?

A: Generally it is 25-35 days for mold making. and the production time is depends on the quantity of production.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

Production Payment: 40% deposit in advance, 60% before sending out the final goods.

Product Categories : Plastic Injection Moulding > Electronic plastic housing

Premium Related Products